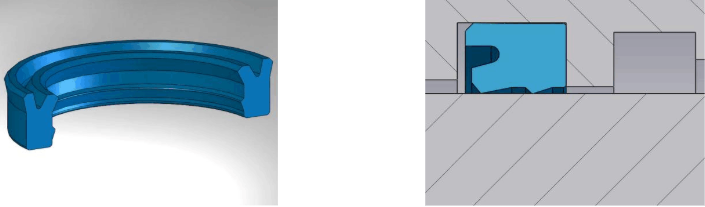

♠Description-Hydraulic PU material U2 Rod Seal | Rod Rings IDI UHS UN U2 Cup Seal

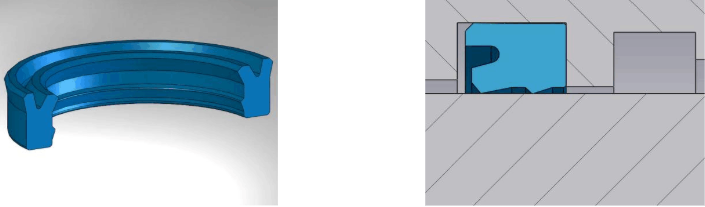

U2 Rod Seal is the result of further development. It has two sealing lips and a strong anti-extrusion retaining ring. This additional lubrication is maintained in the sealing gap due to the action of the two sealing lips. (This greatly reduces dry friction and wear, thus extending the life of the seal.)

Under certain conditions, satisfactory sealing performance can only be achieved by means of seals installed in their respective grooves one after the other. U2, a two-channel lip seal, can replace the expensive series device. Above all, U2 Rod Seal can be used in a variety of applications where the physical properties of ordinary rubber or fabric reinforced rubber are not met.

♥Property

| Material | PU, NBR, FKM |

| Temperature | -35℃~+100℃ |

| Speed | ≤0.5m/s |

| Medium | Hydraulic Oil, Water, Oil, etc |

| Press | ≤40MPA |

| Color | Blue, Green, Black, Red, etc |

| Hardness | 85A shore |

♣Advantage

●Prevent internal pressure generation in the seal●Pressure and oil resistance●Suitable for demanding working conditions●Long service life●A wide range of temperature utilization●Easy to install The above specifications are not complete. Besides, we can customize the non-standard parts for you.

Please feel free to contact me if you are interested.